Special Functions

- Industries & Applications

- Union Tool FAQs

- UTC Literature and Manuals

- Leasing Options

- Get an Equipment Quote

Machine Functions

- Feeding Machines

- Moving Machines

- Coating Machines

- Gluing Machines

- Laminating Machines

- Stacking Machines

- Specialty Machines

Industry/Applications

Coaters

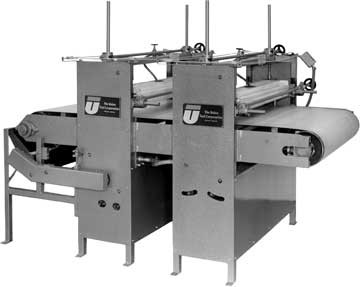

Double Head Roller Coater

This heavy-duty roller coater has two coating heads, for applications requiring a heavier coating layer than would normally be possible with a single-head machine of the same size.

Roll Configuration

In the Model C Single Top Coater Roll Configuration, the liquid coating for the top surface is held in the trough between the top coating roller and its companion doctor roll; the bottom roller simply assists in feeding the substrate through the machine. This Double Head Roller Coater has two of these Model C roll units in series.

Synonyms

Depending on your industry, you may call this a double-headed roll coater, a dual head roll coater, a heavy spread coater, a double coat roller coater, a twin head coater, a double head coater, a dual head heavy spread coater, or a thick-spread double coater (Baseball fans tend to refer to it as a "double header").

Operational Description

For applications requiring a heavy coating, Union Tool has designed the Double Head Roller Coater. The Double Model C Roller Coater shown is designed to apply a rubber compound to paper gaskets. To ensure that enough coating is applied, gaskets are conveyed through two separate coating heads, coating both the top surface and the edges. Some coating material collects on the conveyor belt in this process, so a powered brush system cleans the belt. Both coating assemblies, the powered conveyor and cleaning brush are driven by the same motor. Although this double head roller coater uses the same coating in both heads, each coating assembly could contain different coating materials.

Mechanical Specifications

| SERIES, MODEL NO. |

Series #5, Model CC, 38" |

| OVERALL DIMENSIONS | Length: 96" Width: 50" |

| ROLLER DIMENSIONS | Coating roll: 4" diameter x 38" long Doctor roll: 2.75" diameter x 38" long |

| ROLLER COVERING |

Coating: Smooth ground Thiokol Doctor: Smooth ground chrome-plated steel |

| ROLLER MOUNTING | Spring-loaded rolls mounted in self-aligning bearings |

| ROLLER ADJUSTMENTS | Upper coating roll: single handwheel for vertical adjustment Doctor roll: unifeed adjustment |

| MOTOR & CONTROLS | 2 H.P. dual voltage, 3-phase, 60 cycle Pushbutton 110 volt with disconnect box included |

| THROUGH CONVEYOR | Powered belt conveyor with 36" cleaning brush system to clean belt every revolution |

| OPERATING SPEED |

Variable from 10 to 30 l.f.p.m. |

| PUMPING SYSTEM |

One air pump to pump coating material from supply tank to both coating assemblies |

| SAFETY FEATURES |

Reversing cable around top perimeter of machine. Protective guards and covers on coating assemblies, chain drive and conveyor pulleys |