Special Functions

- Industries & Applications

- Union Tool FAQs

- UTC Literature and Manuals

- Leasing Options

- Get an Equipment Quote

Machine Functions

- Feeding Machines

- Moving Machines

- Coating Machines

- Gluing Machines

- Laminating Machines

- Stacking Machines

- Specialty Machines

Industry/Applications

Movers - Infeed/Outfeed Combination Machine

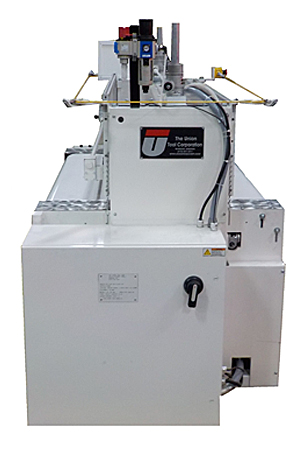

Reverse Glass Roll Coater with Conveyor

A reverse roller coater for application of UV paint, solvent-based and water-based paints to glass plates, panels and sheets. This Union Tool reverse roll coater has integral infeed and outfeed conveyors for direct integration with new or existing production and processing lines.

Roll Configuration

Synonyms

Depending on your application, this unit might be referred to as a UV paint applicator, a glass roll coater, glass paint coater, glass reverse roller coater, in-line roller coater, glass paint spreader, or inline UV roller coater.

Operational Description

The Union Series #5, Model C 14" Roll Coater was specifically designed to apply a smooth and controllable amount of UV paint to the top surface of glass substrates for solar applications such as lighting fixtures. By incorporating an infeed and offbearing conveyor, this roller coater can be placed right in the production line.

The conveyor connects a wash/rinse operation with a UV oven to dry the UV-coated substrates. This is a reverse-action roller coater, which produces a very smooth coated surface. An explosion-proof motor and electricals have been added due to the use of flammable cleanup solvents. A variable speed drive unit allows for increased production without losing coating quality.

Mechanical Specifications

| SERIES, MODEL NO. |

Series #5, Model C, 14" |

| OVERALL DIMENSIONS |

Length: 63" Width: 30" |

| GLASS SIZE RANGE |

Length: 24" Width: 12" |

| ROLLER DIMENSIONS |

Coating roll: 4" diameter x 14" long Doctor roll: 2.75" diameter x 14" long |

| ROLLER COVERING |

Coating: Smooth ground EPDM |

| ROLL CONFIGURATION | Model C (See illustration) |

| ROLL MOUNTING |

Spring-loaded rolls mounted in self-aligning bearings |

| MOTOR & CONTROLS |

1/2 H.P. dual voltage, explosion-proof with 110 volt controls |

| OPERATING SPEED |

Variable from 10 to 30 l.f.p.m. |

| COATING MATERIALS |

UV paints, oil base paints, water base paints |

| SAFETY FEATURES |

Reversing cable around top perimeter of machine. Protective guards on rolls and chain drive |