Special Functions

- Industries & Applications

- Union Tool FAQs

- UTC Literature and Manuals

- Leasing Options

- Get an Equipment Quote

Machine Functions

- Feeding Machines

- Moving Machines

- Coating Machines

- Gluing Machines

- Laminating Machines

- Stacking Machines

- Specialty Machines

Industry/Applications

Function: COAT

Roller Coaters, Roll Coaters, Glass Coaters, and Other Automated Coating Machines.

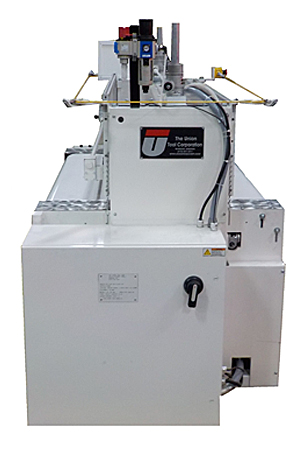

Coating flat sheets, panels and boards with hot melt, adhesive, protective films, paint, and lubricants such as drawing compounds is a common application on many fabricating, production, and processing lines. Union Tool makes many machines for an automated coating process; chief among them are several varieties of roll and roller coaters. Union Tool roller coaters are available in roll widths from 6" to 120".

The terms "roll coater" and "roller coater" mean the same thing: automatic machines that coat one or both sides of a flat substrate - metal, wood, glass, fiberboard, foam, or plastic - with precisely controlled thicknesses of coating material as the sheets are conveyed down a production line. Union Tool uses these terms interchangeably.

FLOORING ROLLER COATER/ LAMINATING MACHINE - The Union Tool Corporation now offers equipment for coating and laminating a variety of flooring products. Union Tool Roller Coaters are used in the production of Luxury Vinyl Tile (LVT) as well as Engineered Flooring and Carpet. These Roller Coaters apply a controlled and consistent amount of hot-melt or water-based adhesive to LVT product to laminate a foam or backer material directly to the LVT product.

HOT MELT ROLLER COATER/HOT ROLL LAMINATOR COMBO MACHINE (SO18547) - Union Tool Corporation has designed a new Lamination machine for the Expanded Polystyrene Industry (EPS) that combines the use of a Hot Melt Roller Coater, to apply hot melt adhesives, and a Hot Roll Laminator, to laminate adhesive backed films, in one machine.

By combining these two different laminating processes, the production floor space is greatly reduced and labor savings can be achieved, which provides reduced equipment and operation costs for Union Tool customers.

HOT MELT ROLLER COATER/LAMINATOR FOR THE AUTOMOTIVE INDUSTRY(16195) - Union Tool has combined a Hot Melt Roller Coater, Unwind Stand, Rotary Laminator, and Automatic Cutoff to produce a laminated truck cover for the Automotive Industry.

A formed composite blank is fed into the Hot Melt Roller Coater which applies a controlled and consistent amount of EVA type of hot melt adhesive to the top surface. The coated blank goes direct into the Rotary Laminator that has an Unwind Stand mounted on the top frame. This Unwind Stand holds the fabric used to cover the coated blank and rolls the fabric onto the blank as it travels through the laminator. As the laminated blank exits the Rotary Laminator an Encoder measures the fabric and will automatically cut the fabric at the proper length. This machine can produce up to six (6) laminated panels per minute.HOT MELT ROLLER COATER/LAMINATOR (16113) - Union Tool has designed a machine that combines a Hot Melt Roller Coater, Unwind Station, and Rotary Laminator all within the same framework. This machine will apply a controlled and consistent amount of PUR hot melt adhesive to the top surface of EPS Foam panels after which a kraft paper is laminated to the coated surface of the foam.

Both the Coater and Laminator have motorized vertical adjustment so the thickness of foam can vary from 0 to 6”. The upper Unwind Station includes an air brake for tension which will eliminate any chance of paper wrinkles. An automatic Edge Guide System has been included to insure edge to edge lamination of the paper to the foam.

Other features include: A.C. Variable speed drive, PLC controller, 7 day timer, automatic adhesive level control, and safety interlocks.

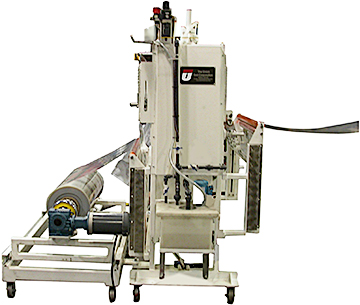

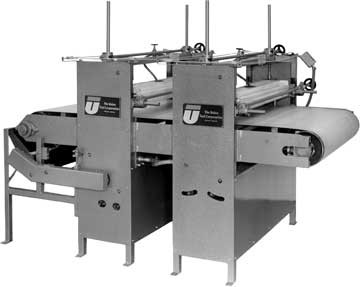

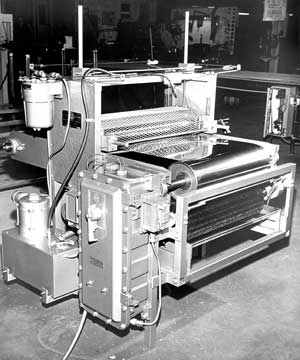

"ONE MAN OPERATION" ROLLER COATER (16197) - Union Tool has added a new feature to an existing Roller Coater used in many Press Room Applications. The picture shows our “One Man Operation” Roller Coater which is specifically designed to apply a controlled and consistent amount of Drawing compound or stamping lubricant onto one or both sides of metal blanks before a press operation. The unique feature of the machine is the “Return Conveyor” system that returns the coated blank to the front of the machine where the press operator fed the blank. The new feature is a set of Flame Hardened Deburring Rolls which flattens any burr on the blank before being coated by the Rubber Coating Rolls. This feature will prolong the life of the rubber coating rolls.

HOT MELT ROLLER COATER/LAMINATOR FOR FLOOR MATS (16032) - The Union Tool Corporation has designed and constructed a system that utilizes a Union Hot Melt Roller Coater and a Union Dual Pinch Rotary Laminator (Pinch Roll). The coater and the laminator are tied together with a through conveyor utilizing a perforated belt and vacuum hold down under the coating area. This insures that the floor mat materials are transported under the coating head where a controlled amount of hot melt adhesive is applied to the top surface only.

After the rubber flooring substrate has been coated, it is transported to an open area on the conveyor between the coater and the laminator. A sensor detects the trailing edge of the coated substrate and stops the conveyor in a pre-determined position. This area allows the top cover to be positioned on the coated floor substrate before being transported into the laminator.

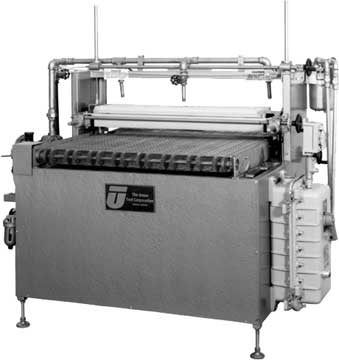

GLASS TRI-COATER (6655)- A new "Tri-Coater" for spandrel glass or transparent glass production and offering controllable, high quality coat thickness. The Tri-Coater's unique design offers two doctor rolls and allows for reverse coating of ceramic frit or silicone based coatings and for direct coat of transparent or etch coatings, all on one machine.

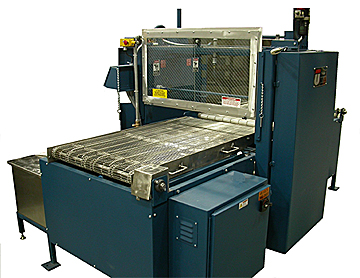

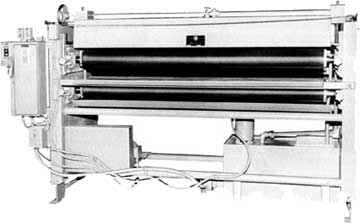

110" WIDE HOT MELT ROLLER COATER (15094) - This picture illustrates a Union Series #65, model A, 110" wide Hot Melt Roller Coater. This machine is designed to apply a PUR hot melt adhesive to one or both sides of composite products for the production of RV components. The machine includes a hot oil heating system that heats all four rolls up to 350 degrees Fahrenheit. The upper coating head is adjustable in relationship to the lower coating head from 0 to 4" through the use of a motorized adjustment hand wheel. Silicone covered coating rolls are used to apply the adhesive.

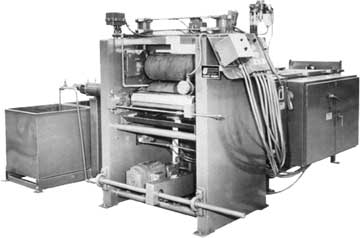

HOT MELT ROLLER COATER (15038) - This Hot Melt Roller Coater used a built-in moving platen to transport and hold down seating material (fabric) through the coater which applied a hot melt adhesive (PUR) to the top surface (backside) of the fabric. After the fabric was coated it would be laminated to the plastic seat using a vacuum press.

The platen was driven separately through the coater by an AC Variable speed motor. Included in the platen were hold down clips that automatically held the front edge of the fabric as the platen moved into the coater. These clips would open on the backside when the platen automatically stopped for the backside operator to remove the coated part. The machine was complete with an operator touch screen which reduced set-up time for the various size parts that were coated.

HOT MELT ROLLER COATER (SO15131) - This Union Hot Melt Roller Coater is designed to apply a reactive hot melt adhesive (PUR) to one side of a foam backed vinyl (IPO) material used for interior automobile door parts. This coater applies a controlled and consistent amount of adhesive onto a continuous roll of IPO material for a Vacuum Forming operation or to individual die cut parts in a Laminating operation.

The adhesive coating can cover the entire width of the part or only a center section. Chrome plated rolls are used to apply the adhesive. These rolls do not require maintenance and are easier to clean.This machine can be supplied with unwind stand for roll goods or clip down conveyor for die cut parts.

AUTOMATIC ROLLER COATER FOR WEB-FED

PLASTIC PACKAGING MATERIALS IN

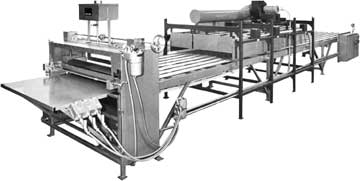

AUTOMATED THERMOFORMING SYSTEMS (PB1004) - This Union Roller Coater is specifically designed to apply a silicone, anti-fog, or anti static coating to one or both sides of plastic packaging materials in a thermoforming process. This coater includes the Unwind stand which holds and feeds out the plastic web controlled by a variable speed motor that changes speed from the direction of a loop control dancer arm.

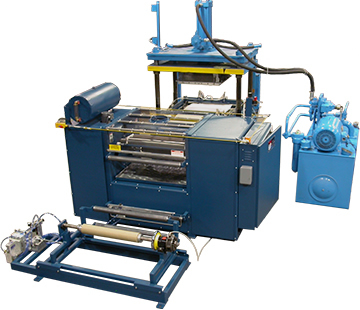

AUTOMATIC HITCH-FEED LAMINATOR SYSTEM FOR COATING PUR HOT-MELT TO WEB-FEED ARTWORK (PB9353) - This complete laminator system pulls artwork from an unwind station and coats the top surface with PUR hot-melt adhesive in a specified area, then pulls the spot-coated artwork into a hydraulic die-cut and lamination press.

DUAL HEAD STEEL STRIP UV ROLLER COATER (PB6868) - This dual-head reverse roll coater is designed to apply an extremely smooth, controllable, pinhole-free application of UV and other coatings to one or both sides of steel strips.

110-inch DUAL HEAD HOT MELT ROLLER COATER (PB4401) - A really big hot melt roller coater for the lamination of wall panels, ceiling panels and floor panels in the recreational vehicle (RV), mobile home, and fifth-wheel towables industries. Coats one side or both sides of the substrate in a single pass; single or double sided coating modes selectable with the flip of a switch.

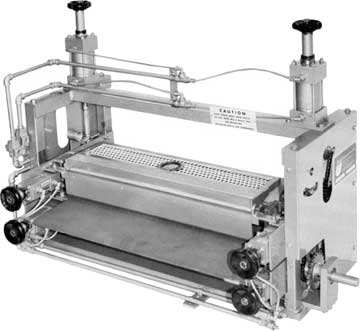

2-SIDED RESIN ADHESIVE ROLLER COATER (PB18453) - An adhesive roller coater designed for applying a precise coating of resin adhesive to both sides of the substrate in one operation. (The illustrated machine has been optimized for coating clutch and brake facing plates with resin adhesive on both sides, but can be easily adapted for other coatings on other substrates.)

1- or 2-SIDED ADHESIVE ROLL COATER (PB1977) - An adhesive roll coater designed for applying a precise coating of water-based, solvent-based or phenolic resin adhesive to either side or both sides of the substrate in one operation.

BLISTER PACK / SKIN PACK COATING SYSTEM (PB2019) - An automated machine that applies liquid vinyl and heat sealing adhesive to card stock to make blister packs or skin packs for retail display hanger cards or other product packaging.

DOUBLE HEAD, HEAVY SPREAD ROLLER COATER (PB17312) - This heavy-duty roller coater has two coating heads, for applications requiring a heavier coating layer than would normally be possible with a single-head machine of the same size.

PRESS BLANK FEEDER COATER (PB15093) - A combination metal blank de-stacker, drawing compound coater, and blank feeder all in one machine makes the Union Tool Press Blank Feeder Coater a natural for metalforming and metal stamping operations.

PCB ROLLER COATER (PB2054) - This roller coater is for in-line application of coatings and protective sealants to the top surface of printed circuit boards as they travel down a production or assembly line. The coater has both infeed and outfeed conveyor sections which match the pass line height of the main conveyor line, and are synchronized to the line speed.

METAL BLANK IN-LINE STOCK LUBRICATOR (PB2010) - Union Tool Inline Stock Lubricators apply a precise film coating of drawing compound or stamping lubricant to metal blanks and sheets just before they enter the stamping or drawing press. These compact units go between the stock feeder (typically a coil straightener) and the press.

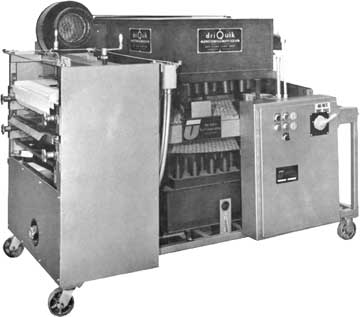

ROLL COATER - FLASH-OFF DRYER (PB16512) - A metal blank lubricant roll coater with integrated flash off dryer ovens (top and bottom). Lubricates and dries metal blanks prior to drawing or stamping operations. The flash-off dryer ovens combine infrared heat and moving air to flash dry the coated blanks; variable heat.

ROLLER COATER for STAMPING LUBRICANT and

DRAWING COMPOUND application (PB2056) - A roller coater for the application of drawing compound or stamping lubricant to metal sheets prior to metal forming operations. Includes infeed and outfeed conveyors. Coats top side, bottom side, or both in a single pass.

SELF-CLEANING ROLLER COATER (PB2033) - A stainless steel through conveyor belt with an integrated scrubbing brush roller and squeegee is the key to keeping things clean as the central roll coater mechanism applies a thin film of adhesive coating to the top surface of the gasket substrate material.

REVERSE GLASS ROLLER COATER (PB16660) - A roller coater especially designed to apply paint and other coatings to glass plates and panels. While there are many applications for processing glass sheets in this manner, this particular machine is used in the creation of spandrel glass panels for buildings and architecture.

REVERSE GLASS ROLL COATER w/ conveyors (PB17934) - A reverse roll coater for application of UV paint, solvent-based and water-based paints to glass plates, panels, panes and sheets. This Union Tool reverse roller coater has integral infeed and outfeed conveyors for direct integration with new or existing production and processing lines.

ROLLER COATER Series 15 (PB2037) - A roller coater for the application of paints, drawing compounds, lubricants, adhesives and similar coatings to metal sheets, wood panels, and other flat surfaces up to 62" wide. Both single-sided and double-sided models are available, as either stand-alone or in-line units with infeed and offbearing conveyors.

ROLLER COATER Series 45 - Model A (PB2057)- An extremely rugged, heavy-duty roller coater for applying lubricant to heavy gauge hot roll blanks.

ROLLER COATER Series 45 - Model B (PB2035) - An extremely rugged, heavy-duty roller coater for panels, sheets and coils up to 98" wide and up to 2" thick. For coating lubricants, drawing compounds, and synthetic oils.

SILICONE ROLL COATER (PB3360) - Applies a silicone release coating to the top side, the bottom side, or both sides of plastic web material or sheet plastic before it is formed into packaging containers.