Special Functions

- Industries & Applications

- Union Tool FAQs

- UTC Literature and Manuals

- Leasing Options

- Get an Equipment Quote

Machine Functions

- Feeding Machines

- Moving Machines

- Coating Machines

- Gluing Machines

- Laminating Machines

- Stacking Machines

- Specialty Machines

Industry/Applications

Function: MOVE

Automated, Automatic Conveyor Lines for Panels, Sheets, Plates and Boards.

Moving work pieces down a production line or processing line typically involves conveyors of one description or another, and Union Tool has made a specialty of conveyorizing flat panels, sheets, plates and boards.

Beyond straight conveyor line sections - which Union Tool provides in all varieties from skate wheels to motorized belts - we also provide automatic or automated conveyor line elements that turn, change flow direction, auto-return, buffer and accumulate. In addition, many of our machines include in-feed and out-feed conveyors as either standard features or optional accessories.

Here are a few samples that illustrate the MOVE function in action:

Infeed / Outfeed Combination Machines

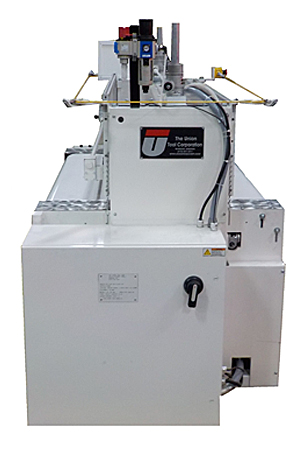

Series #5 Roller Coater w/Infeed Conveyor - This roller coater is for in-line application of paints, drawings compounds, lubricants, adhesives, and similar coatings to the top surface only of flat substrates. These substrates can include metal sheets, wood panels, fiber board, plastic sheets, glass, foam, and many other flat surface materials. The coater incorporates an infeed conveyor section in which assists an operator feeding materials into the roller coater.

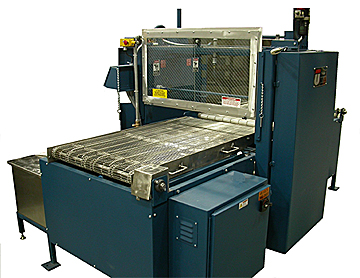

REVERSE GLASS ROLL COATER w/ Conveyors - A reverse roll coater for application of UV paint, solvent-based and water-based paints to glass plates, panels, panes and sheets. This Union Tool reverse roller coater has integral infeed and outfeed conveyors for direct integration with new or existing production and processing lines.

RETURN FEED CONVEYOR for Roller Coaters - This special conveyor can be adapted to any new Union Tool roller coater. One person can handle both infeed and outfeed, thanks to a unique slanted conveyor that accepts the work piece as it is fed through the roll coater, then drops down to return the finished piece to the operator and retracts to the start position to accept the next piece.

ROLLER COATER for STAMPING LUBRICANT and DRAWING COMPOUND application, w/ Conveyors - A roller coater for the application of drawing compound or stamping lubricant to metal sheets prior to metal forming operations. Includes infeed and outfeed conveyors. Coats top side, bottom side, or both in a single pass.

Conveyors

LAYUP CONVEYOR - A powered roller layup conveyor that will transport core wood planks from a Union Hot Melt Roller Coater to a Union Multi Nip Rotary Laminator.

BELT TRANSFER CONVEYOR - A powered belt conveyor to transfer different flat substrate materials from one processing system to another.

ROLLER TRANSFER CONVEYOR - For wider substrate materials, our powered roller transfer conveyor will transport different flat substrate materials from one processing system to another with ease!

COMBINATION 90° / STRAIGHT CONVEYOR - A versatile conveyor section that can send flat panels in either of two directions - straight ahead, or at a 90 degree angle. A flexible and effective conveyor line flow control.

CONVEYOR ACCUMULATION STATION - A conveyor line accumulation station that holds flat panels such as printed circuit board substrates as they come off a machine or conveyor and then releases them one at a time to a downstream conveyor line or processing machine as they are called for.