Special Functions

- Industries & Applications

- Union Tool FAQs

- UTC Literature and Manuals

- Leasing Options

- Get an Equipment Quote

Machine Functions

- Feeding Machines

- Moving Machines

- Coating Machines

- Gluing Machines

- Laminating Machines

- Stacking Machines

- Specialty Machines

Industry/Applications

Function: SPECIALTY

Specialty Automated Machines for Custom Applications from Union Tool.

Electrical and electronic programmable machine controllers and flow control for conveyorized sheet and panel production lines and processing lines. Specialty automated machines for custom applications, from foam scrap disposal to complete, multi-machine systems. Here are some examples:

ENGINEERED ELECTRICAL CONTROLS - Engineered electrical and electronic controls are the brains behind automated processing machines like those you'll find here at Union Tool. They provide the accuracy, precision and repeatability that make these machines profitable and dependable.

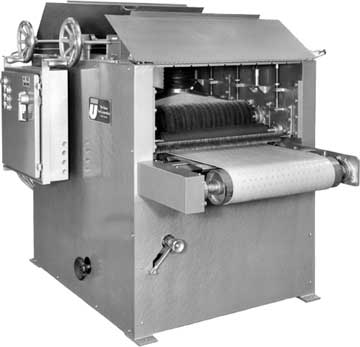

WIRE BRUSH MACHINE for brushed aluminum finishes - Not exactly a coater, but it does cover the surfaces of aluminum sheets with a handsome brushed aluminum texture. Dual stainless steel brushes apply a scratch finish texture on aluminum sheets to produce that "brushed aluminum" look.

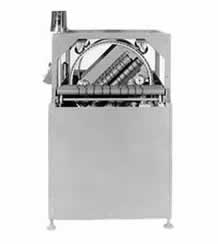

EPS FOAM WASTE DISPOSAL MACHINE - EPS foam waste disposal made easy - melt it into sheets and stack it! Just dump the EPS bead scrap into this machine, and out come compacted sheets that pile neatly in minimum space, saving plant space and disposal costs.

COMBINATION 90° / STRAIGHT CONVEYOR - A versatile conveyor section that can send flat panels in either of two directions - straight ahead, or at a 90 degree angle. A flexible and effective conveyor line flow control.

90° TURN CONVEYOR SECTION - A conveyor section that changes the direction of the conveyor line - 90 degrees to the left or right - while keeping the pieces oriented in the same direction relative to the conveyor bed. Add two of these in sequence to turn the line 180°. Versatile production line layout control.

CONVEYOR ACCUMULATION STATION - A conveyor line accumulation station that holds flat panels such as printed circuit board substrates as they come off a machine or conveyor and then releases them one at a time to a downstream conveyor line or processing machine as they are called for.

TRANSFER ACCUMULATION CONVEYOR - Transfers thin panels (e.g.: printed circuit board substrates) from the outfeed conveyor of one process (e.g.: curing oven) to the infeed conveyor of the next process (e.g.: automated mask printer), while providing a 100-panel buffer accumulator to even out transcient line speed fluctuations between the two processes.

PCB TURNOVER Model SS - This in-line device turns printed circuit boards over 180 degrees (180°) as they pass down the conveyor on the processing or assembly line. It does this while keeping the PCB registration holes in the proper position, and edge-handling assures that the surface of the board is protected.

Complete Systems - Multi-Machine Production Lines.

Electrical and electronic programmable machine controllers and flow control for conveyorized sheet and panel production lines and processing lines. Specialty automated machines for custom applications, from foam scrap disposal to complete, multi-machine systems. Here are some examples:

The illustration above shows a dozen Union Tool machines configured as a self-contained production line. All of the elements share the same pass line height, and are electrically connected so the entire line runs as a unit. Using flow control conveyor sections, Union Tool can not only link various processes together into a fully automated production line, but can do so making the most efficient use of your existing plant floor. If you have existing machines that you'd like to incorporate, we can design your new line around them; if you're building a new line from scratch, we can engineer a complete Union Tool solution from head to tail.