Special Functions

- Industries & Applications

- Union Tool FAQs

- UTC Literature and Manuals

- Leasing Options

- Get an Equipment Quote

Machine Functions

- Feeding Machines

- Moving Machines

- Coating Machines

- Gluing Machines

- Laminating Machines

- Stacking Machines

- Specialty Machines

Industry/Applications

Function: STACK

Automatic Sheet Stackers for Wood, Plastic, Fibre and Metal Sheets, Panels, Boards and Plates.

This is the flip side of feeders, which typically come at the head of processing lines; stackers typically come at the end of the line, where the processed sheets or panels come off the line and are stacked up for packaging, warehousing or delivery. Union Tool makes stackers for all sizes and types of sheets, panels boards and plates, made of wood, plastic, fibre and metal.

Here are a few samples that illustrate the STACK function in action:

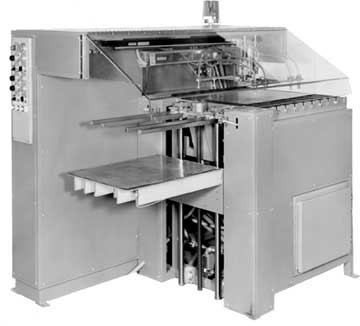

AUTOMATIC SHEET STACKER (PB15392) - This automated machine stacks sheets as they exit processing machines or a conveyor line. The pictured machine is specifically for printed circuit boards, but the concept is easily adapted to other materials and applications.

DUAL STATION STACKER (PB21439) - This dual station stacker stacks metal blanks as they come from a coil-fed blanking press, loading an operator-designated number of blanks onto each of two stacking carts. When the first cart is filled, the machine automatically switches over to filling the second cart.