Special Functions

- Industries & Applications

- Union Tool FAQs

- UTC Literature and Manuals

- Leasing Options

- Get an Equipment Quote

Machine Functions

- Feeding Machines

- Moving Machines

- Coating Machines

- Gluing Machines

- Laminating Machines

- Stacking Machines

- Specialty Machines

Industry/Applications

Coaters

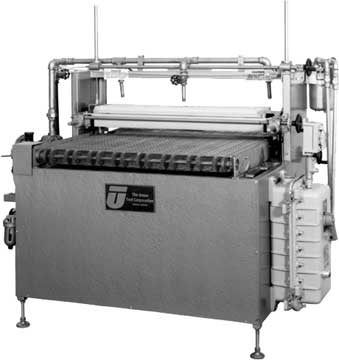

2-Sided Adhesive Roller Coater

An adhesive roller coater designed for applying a precise coating of resin adhesive to both sides of the substrate in one operation.

In the Model A Double Coater Roll Configuration, the liquid coating is held in the troughs between the coating rolls and their companion doctor rolls, top and bottom.

Synonyms

Depending on your industry, you may call this a roller coater, a roll coater, an adhesive spreader, an adhesive roll coater, a glue coater, a glue spreader, a two-sided adhesive coater, a two-sided roll coater, or a double-sided roller coater.

Operational Description

The Union Adhesive Roller Coater applies a controlled amount of resin adhesive to both sides of clutch and brake facing plates in a single pass. The 36" work area allows several rows of plates to be fed across the width of the coater simultaneously. A recirculating pumping system automatically pumps resin up to each coating assembly. Removable conveyors on both the front and back of the coating assemblies provide quick and easy adhesive cleanup.

Mechanical Specifications

| SERIES, MODEL NO. |

Series #5, Model A, 38" |

| OVERALL DIMENSIONS | Length: 50" Width: 60" |

| ROLLER DIMENSIONS | Coating rolls: 4" diameter x 38" long Doctor rolls: 2.75" diameter x 38" long |

| ROLLER COVERINGS | Coating roll: smooth ground EPDM Doctor roll: smooth ground chrome-plated steel |

| ROLL MOUNTING |

Spring-loaded rolls mounted in self-aligning bearings |

| ROLL ADJUSTMENTS | Upper coating assembly has top single handwheel for vertical adjustment. Both doctor rolls incorporate unifeed adjustments |

| THROUGH CONVEYOR | Stainless steel wire mesh conveyor belt transports clutch plates through coater |

| MOTOR & CONTROLS | Rolls and conveyor powered by 1 H.P. dual voltage, 3-phase, 60 cycle explosion-proof motor. 110 volt explosion-proof pushbuttons and disconnect box included |

| SPEED | Variable from 15 to 45 l.f.p.m. |

| PUMPING SYSTEM |

One double diaphragm air pump to pump adhesive from supply tank to both coating assemblies |

| SAFETY FEATURE |

Reversing cable around top perimeter of machine. Protective guards and covers on coating assemblies and chain drive |

| SPECIAL FEATURE | Both infeed and offbearing conveyors are easily removable for cleaning purposes |