Special Functions

- Industries & Applications

- Union Tool FAQs

- UTC Literature and Manuals

- Leasing Options

- Get an Equipment Quote

Machine Functions

- Feeding Machines

- Moving Machines

- Coating Machines

- Gluing Machines

- Laminating Machines

- Stacking Machines

- Specialty Machines

Industry/Applications

Roller Coater

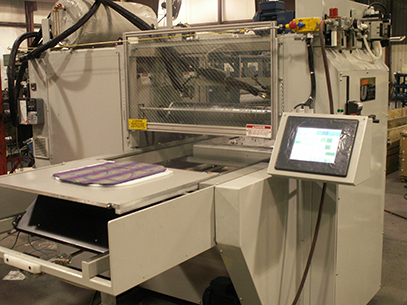

Hot Melt Roller Coater (15038)

This Hot Melt Roller Coater used a built-in moving platen to transport and hold down seating material (fabric) through the coater which applied a hot melt adhesive (PUR) to the top surface (backside) of the fabric. After the fabric was coated it would be laminated to the plastic seat using a vacuum press.

The platen was driven separately through the coater by an AC Variable speed motor. Included in the platen were hold down clips that automatically held the front edge of the fabric as the platen moved into the coater. These clips would open on the backside when the platen automatically stopped for the backside operator to remove the coated part. The machine was complete with an operator touch screen which reduced set-up time for the various size parts that were coated.