Special Functions

- Industries & Applications

- Union Tool FAQs

- UTC Literature and Manuals

- Leasing Options

- Get an Equipment Quote

Machine Functions

- Feeding Machines

- Moving Machines

- Coating Machines

- Gluing Machines

- Laminating Machines

- Stacking Machines

- Specialty Machines

Industry/Applications

Movers / Coaters

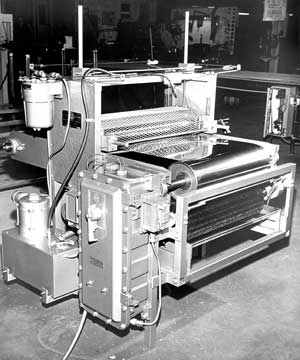

Self-Cleaning Roller Coater for Gasket Adhesive Application

A stainless steel through conveyor belt with an integrated scrubbing brush roller and squeegee is the key to keeping things clean as the central roll coater mechanism applies a thin film of adhesive coating to the top surface of the gasket substrate material.

Roll Configuration

In the Model C Single Top Coater Roll Configuration, the liquid coating for the top surface is held in the trough between the top coating roller and its companion doctor roll; the bottom roller simply assists in feeding the substrate through the machine.

Synonyms

Adhesive roller coater, gasket roll coater, self-cleaning adhesive coater, gasket coater, adhesive applicator, and self-cleaning gasket adhesive film spreader.

Operational Description

This special Series #5, Model C, 26" Roller Coater was designed for the application of adhesive to thin gasket stock.

The special feature of this machine is the 24"-wide stainless steel through conveyor belt with an automatic belt cleaning system. As the conveyor belt becomes contaminated with the coating material, a brush revolving in the reverse direction picks up cleaning solvent from a pan and scrubs the belt. A rubber squeegee, under spring tension, then removes the wet solvent film, leaving the conveyor clean and ready to accept additional substrates for coating.

This machine is also equipped with explosion-proof electricals, an explosion-proof safety control and an explosion-proof recirculating system to supply the coating material to the coating area. Additional features, such as the single handwheel control to regulate the upper coating assembly in relation to the conveyor belt, and a unifeed adjustment to control the material thickness being applied to the substrate, have also been installed.

As with all of the Union roller coaters, safety features such as a fused disconnect, magnetic line starters, 110 pushbutton control and the guarding of all pinch points has been incorporated.

Once again the Union Tool Corporation has provided modern industry with an efficient roller coater in response to its production demands.