Special Functions

- Industries & Applications

- Union Tool FAQs

- UTC Literature and Manuals

- Leasing Options

- Get an Equipment Quote

Machine Functions

- Feeding Machines

- Moving Machines

- Coating Machines

- Gluing Machines

- Laminating Machines

- Stacking Machines

- Specialty Machines

Industry/Applications

Movers / Coaters

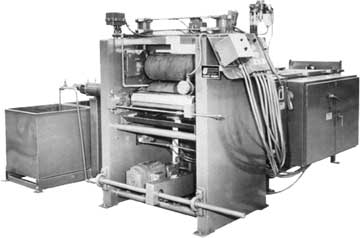

Hot Roll Blanks Lubricant Roller Coater Series 45 - Model A

An extremely rugged, heavy-duty roller coater for applying lubricant to heavy gauge hot roll blanks.

Roll Configuration

Synonyms

Depending on your industry, you may call this a hot roll blank lubricator, a roller coater, a roll coater, heavy-duty coater, or a heavy-duty roller coater.

Operational Description

The Union Series #45, Model A, Special Roller Coater was built for a special application. This coater applies a lubricant to heavy gauge hot roll blanks, changing an energy wasting hot form operation into a cold form operation using very little energy and requiring no additional labor.

The lubricant is premixed in tanks and then pumped to the two independent coating heads. Level controls operate valves that automatically maintain the level of lubricant in the crotches of the coating heads without damage or overflow.

A custom drive shaft on this coater drives a short infeed conveyor section and a roll-type offbearing conveyor section. As the blanks move down an existing conveyor driven by the coater, they enter the nip of the coating rolls. This nip is controlled automatically by air cylinders with screw mechanical stops. As the blank is being coated, it is transported on the offbearing roller-type conveyor up against a backstop.The backstop automatically signals the conveyor to reverse, and the coating rolls to pop open. This moves the sheet back through the coater onto the short infeed conveyor section, where it is then stopped and moved by chains at a 90-degree angle into the press.

The variable DC drive, the automatic pop-open coating heads, the recirculating system and offbearing conveyor are but a few of the options available on Union Tool roller coating equipment.

We pride ourselves on the ability to build heavy-duty roller coating equipment to meet individual applications, maximizing efficiency, reducing costs and saving labor. Submit your requirements to the Union Tool Corporation-we'll offer our ideas and cost estimate for equipment designed to meet your individual needs.