Special Functions

- Industries & Applications

- Union Tool FAQs

- UTC Literature and Manuals

- Leasing Options

- Get an Equipment Quote

Machine Functions

- Feeding Machines

- Moving Machines

- Coating Machines

- Gluing Machines

- Laminating Machines

- Stacking Machines

- Specialty Machines

Industry/Applications

Feeders

Union Sheet Feeder

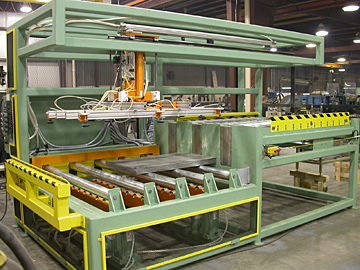

Manual feeding of metal sheet blanks is labor intensive, potentially slow or inefficient. There is injury potential as well. The Union Sheet Feeder is specifically designed to automatically destack, align and feed steel sheets. The feeder will feed sheets ranging in sizes from 20" to 44" wide and 60" to 76" long with thicknesses varying from .050" to .125". A complete stack can be a maximum of 16" high and weigh up to 8,000 pounds. Cycle time is a maximum of five sheets per minute.

Operational Description

The sheet blanks are delivered from the side to a powered roller conveyor using a forklift. A lower roller conveyor rises to lift the load. A centering device moves the load to the machine center. It is very important to have the blanks on center before delivery to the roll forming machine. Once the blanks are centered, the original powered roller conveyor delivers the stack to a backstop, which features magnetic sheet separators. These separate the top sheet from the stack to be delivered to the roll formers.

A vacuum head gentry, with eight vacuum cups mounted to the head, moves over the blank stack and lowers to pick up the top sheet. It then moves the single blank to a new conveyor featuring idler rollers and a chain conveyor with a pushing device or "dog". The chain conveyor features two dogs; one pushes the blank to the roll former and then falls out of the way, while the second dog comes up from behind to push the next blank. Vertical centering devices insure the blank is centered and secure until it is delivered to the roll forming press. When the sheet is drawn into the press, the centering devices separate/open to make room for the next sheet.

The sheet feeder is equipped with a double sheet detector to insure that only one sheet at a time is delivered. If two sheets are detected the operation will stop. The Union Sheet Feeder - reduces labor costs; increases worker safety and production efficiency.