Special Functions

- Industries & Applications

- Union Tool FAQs

- UTC Literature and Manuals

- Leasing Options

- Get an Equipment Quote

Machine Functions

- Feeding Machines

- Moving Machines

- Coating Machines

- Gluing Machines

- Laminating Machines

- Stacking Machines

- Specialty Machines

Industry/Applications

Laminators

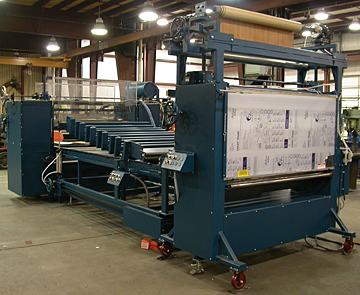

Union Veneer/Vinyl Laminating System

Boost productivity and product quality with this Union equipment package. This Veneer/Vinyl Laminating System contains a Union Hot Melt Roller Coater, Union Powered Lay-up Conveyor and Union Rotary Laminator to laminate several different core materials to a variety of different veneers and vinyl materials.

Operational Description

The laminating system will produce a panel with a maximum size of 60" wide x 120" long and a maximum thickness up to 4".

Hand-fed core materials such as sheets of plywood, medium density fiberboard (MDF) and some metals, like aluminum, are run through a Hot Melt Roller Coater. Adhesive is applied in a smooth, even and controlled amount to the top of the core material, with the material coming out on a Semi-automatic Lay-up Conveyor. The conveyor moves the coated core to a common edge guide to insure proper positioning for the application of the veneer top layer. The conveyor then moves the core to the backstop.

The upper veneer rack conveyor is angled and adjustable to aid the operator in the proper delivery of the top laminate layer. The upper veneer and lower laminated core are mated with upper and lower rollers. The lower powered conveyor then feeds the laminated panel to the rotary laminating press in order to deliver the final product.

This system also includes a vinyl roll applicator. It features a tension control that eliminates wrinkles during the application of the vinyl to the coated core material.