Special Functions

- Industries & Applications

- Union Tool FAQs

- UTC Literature and Manuals

- Leasing Options

- Get an Equipment Quote

Machine Functions

- Feeding Machines

- Moving Machines

- Coating Machines

- Gluing Machines

- Laminating Machines

- Stacking Machines

- Specialty Machines

Industry/Applications

Specialty

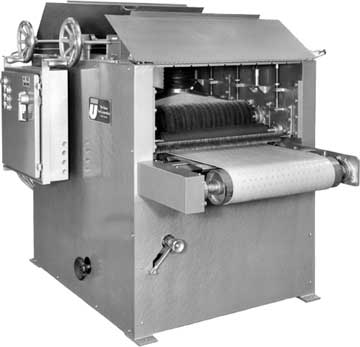

Wire Brush Machine

Dual stainless steel brushes apply a scratch finish texture on aluminum sheets to produce that "brushed aluminum" look.

Synonyms

Aluminum brush texturizer, wire brusher, scratch finisher, scratch brush, aluminum scratch finish brush machine, or brushed aluminum surface finisher.

Operational Description

The Union Wire Brush Machine is designed to put a scratch finish on aluminum sheets. The machine incorporates two stainless steel brushes to obtain the desired brush finish. Along with the appropriate number of hold-down rolls there is a perforated belt to hold the thin sheets flat as they pass under each wire brush.

There is also a high-volume blower to pull a vacuum through the perforations at each brush area. A brush on the offbearing side removes static from the sheet as it leaves the machine. Each brush is adjustable vertically to allow for various thicknesses of material.

The brushes are driven by a 10 H.P. motor while the conveyor and vacuum system are each driven by a 1 H.P. motor.

Mechanical Specifications

| SERIES, MODEL NO. |

Series #35-26" Double Roll Machine |

| OVERALL DIMENSIONS |

Length: 71" Width: 45" Height: 60" |

| PRODUCT SIZE RANGE |

Up to 26" in width and 15" minimum length, .010 to .125 in thickness |

| BRUSH ROLL DIMENSIONS |

Stainless steel brush roll is 8" in diameter x 26" long |

| HOODS | Sheet metal enclosing both brushes with 8" dust opening |

| PASS LINE HEIGHT |

34" |

| BRUSH ROLL MOUNTING |

Spring-loaded rolls mounted in self-aligning bearings |

| MOTORS AND CONTROLS |

One 10 H.P. dual voltage TEFC Two 1 H.P. dual voltage TEFC 110v pushbutton controls |

| OPERATING SPEED |

Variable speed on brushes 500 to 1500 RPM Belt speed variable from 10 to 100 l.f.p.m. |

| SAFETY FEATURES |

Protective guards on rolls and chain drive Static eliminator on infeed and offbearing sides of the conveyor |